Sawtooth Robotics to Debut Next-Gen PrePlater at BCMC 2025

Sawtooth Robotics is excited to announce that we will be exhibiting at the Building Component Manufacturers Conference (BCMC) 2025, the premier event for the truss and component industry.

Join us from September 29th to October 3rd for an exclusive first look at our groundbreaking automated solutions.

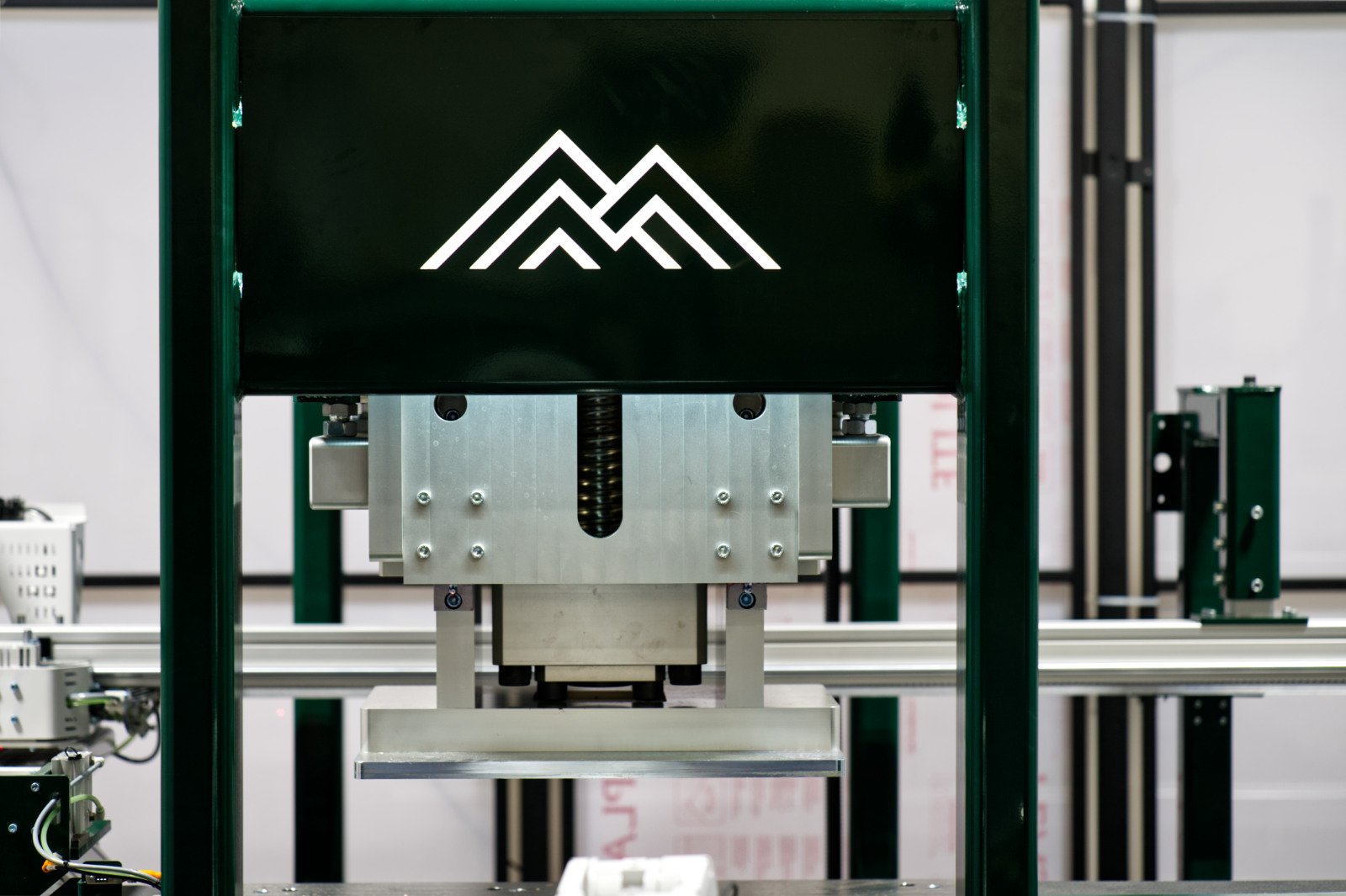

See the Future of Pre-Plating Live

Visit our booth to witness the live debut of our next-generation Automated PrePlater system. Get a firsthand look at our custom servo press in action, delivering unmatched precision and consistency in pressing nail plates into boards. This system is engineered to help manufacturers like you:

-

Cut downtime and reduce labor challenges.

-

Increase production efficiency and throughput.

-

Process both roof and floor members (2×3–2×12) in one versatile system.

-

Achieve consistent pre-plating that reduces bottlenecks at assembly tables.

The new Sawtooth PrePlater is designed for speed, simplicity, and versatility with intelligent sequencing software and a robust design for higher throughput.

Meet Us at BCMC 2025

This is your chance to see the technology that is shaping the future of component manufacturing. We invite you to stop by our booth to see automation in action, ask our experts your questions, and discover the right solution for your plant’s needs.

Will we see you there? Let us know if you’re attending!

Sawtooth Robotics is excited to announce that we will be exhibiting at the Building Component Manufacturers Conference (BCMC) 2025, the premier event for the truss and component industry.

Join us from September 29th to October 3rd for an exclusive first look at our groundbreaking automated solutions.

See the Future of Pre-Plating Live

Visit our booth to witness the live debut of our next-generation Automated PrePlater system. Get a firsthand look at our custom servo press in action, delivering unmatched precision and consistency in pressing nail plates into boards. This system is engineered to help manufacturers like you:

-

Cut downtime and reduce labor challenges.

-

Increase production efficiency and throughput.

-

Process both roof and floor members (2×3–2×12) in one versatile system.

-

Achieve consistent pre-plating that reduces bottlenecks at assembly tables.

The new Sawtooth PrePlater is designed for speed, simplicity, and versatility with intelligent sequencing software and a robust design for higher throughput.

Meet Us at BCMC 2025

This is your chance to see the technology that is shaping the future of component manufacturing. We invite you to stop by our booth to see automation in action, ask our experts your questions, and discover the right solution for your plant’s needs.

Will we see you there? Let us know if you’re attending!